Project Background

Saint Mother Teresa’s Missionaries of Charity (MoC) Center in Ethiopia has a branch located in Semera, the capital of the Afar Region. At the time of the project, the Center serves the poor, destitute, and disabled from all over the region and operates a kindergarten school for 60 students. The Center has a population of approximately 150 patients in a given day. This desert region gets very little rainfall and most of the year experiences very high temperatures approaching 120 degrees.

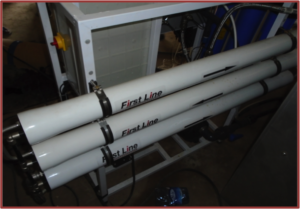

There is a well on the property but the water is unfit for consumption due to high levels of salts and minerals that surpass the allowable limits established by the World Health Organization. The old water purification and sanitation system had been inoperable for over a year and needed to be replaced with a functional, simple-to-operate system. Our new innovative RAW system allows the Center to distribute clean purified drinking water to the community once again.